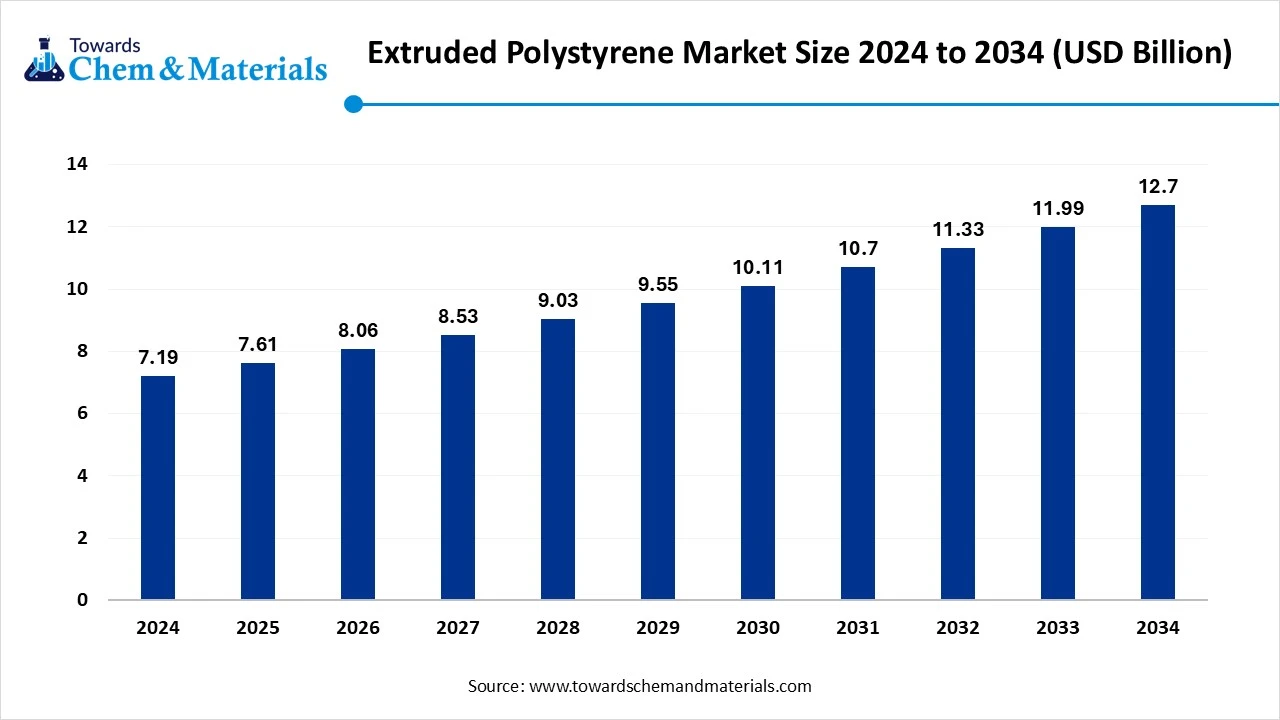

Extruded Polystyrene Market Size to Worth USD12.70 Bn by 2034

According to Towards Chemical and Materials Consulting, the global extruded polystyrene market size was accounted for USD 7.61 billion in 2025 and is expected to be worth around 12.70 billion by 2034, growing at a compound annual growth rate (CAGR) of 5.85% from 2025 to 2034.

Ottawa, Dec. 01, 2025 (GLOBE NEWSWIRE) -- The global extruded polystyrene market size was valued at USD 7.61 billion in 2025 and is predicted to increase from USD 8.06 billion in 2026 is anticipated to reach around USD 12.70 billion by 2034, growing at a compound annual growth rate (CAGR) of 5.85% over the forecast period 2025 to 2034. Europe dominated the Extruded Polystyrene market with the largest revenue share of 35% in 2024. The growth of the extruded polystyrene (XPS) market is being driven primarily by rising demand for high-performance insulation materials in the construction and building sector, where XPS is valued for its superior thermal resistance, moisture resistance, and durability. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/5798

What is Extruded Polystyrene?

The extruded polystyrene (XPS) market is witnessing steady growth due to its strong demand in construction, packaging, and industrial applications, driven by its excellent thermal insulation, moisture resistance, and structural strength. XPS is widely used in residential and commercial buildings, roofing, flooring, and cold-chain packaging because of its lightweight, cost-effective, and energy-efficient properties. Advances in manufacturing technologies and the development of environmentally friendly, flame-retardant formulations are enhancing product performance and sustainability. Increasing urbanization, infrastructure expansion, and regulatory focus on energy-efficient buildings are further supporting market growth, positioning XPS as a key material in modern construction and packaging solutions.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

Extruded Polystyrene Market Report Highlights

- By region, Europe dominated the market in 2024. The Europe region held approximately 35% share in the market in 2024. The expanding construction sector fuels the growth.

- By product type, the boards segment dominated the market in 2024. The boards segment approximately held 55% share in the market in 2024. The growing use of construction fuels the growth of the market.

- By application, the residential construction segment dominated the market in 2024. The residential construction segment approximately held 40% share in the market in 2024. The growing population and demand fuel the growth.

- By end use, the wall & roof insulation segment dominated the market in 2024. The wall & roof insulation segment approximately held 50% share in the market in 2024. The benefits and high-performance properties fuel the growth of the American market.

- By distribution channel, the construction material distributors segment dominated the market in 2024. The construction material distributors segment approximately held 60% share in the market in 2024. The growing demand due to increased construction activities boosts the growth of the market.

Extruded Polystyrene (XPS) Thermal Insulation Products

Styropan XPS extruded polystyrene is a synthetic material that has gained global recognition and is extensively used in various construction applications. It is a foam-based substance with a "closed cell structure." Through a process called polymerization and continuous extrusion, it transforms into panels designed for thermal insulation.Due to its remarkable ability to insulate against heat and its strong mechanical properties, Styropan XPS is a popular choice in a wide range of applications. It provides dependable construction solutions for architects, civil engineers, contractors, and technicians.

Styropan XPS extruded polystyrene stands out from other insulation materials due to its distinct properties:

- It is environmentally friendly, containing a portion of recycled raw materials.

- It possesses high mechanical strength, making it capable of withstanding heavy loads. This feature is especially important for areas like terraces, floors, and industrial facilities.

- It exhibits extremely low water absorption, making it ideal for insulating materials used in applications such as underground walls and inverted or green roofs.

- It has a very low thermal conductivity coefficient, which minimizes heat transfer between the building and its surroundings. This characteristic ensures optimal thermal comfort with minimal energy consumption.

- It is fully recyclable and does not contain harmful substances like chlorofluorocarbons (CFCs), hydro-chlorofluorocarbons (HCFCs), or hydro-fluorocarbons (HFCs).

- It demonstrates excellent adhesion to concrete or mortars and can be manufactured without the extrusion skin. It can also be produced with an embossed, rhomboidal surface, as seen in the Styropan XPS ETICS EMB variant.

Other Properties in Extruded Polystyrene Market

- Strength. Extruded polystyrene is a rigid material with a very high compressive strength. The product’s closed-cell cross section contributes to its impressive strength and insulating properties. Products are available in a range of compressive strengths to meet different applications. Extruded polystyrene foam board can be manufactured up to 100 psi or more.

- Inhibits growth of biological air contaminants. Water absorption promotes the growth of many organisms such as mold, mildew, and fungi. XPS foam board is water resistant and can prevent the growth of unwanted organisms. This makes it ideal for the roofing industry.

- Durability. It will not rot or decompose over time because of its durability. It is resistant to microorganisms in the soil and it isn’t attractive to rats and other animals as a source of food. It typically has a lifespan of up to 50 years.

- Size and density. XPS can be manufactured with or without plastic facings. It is most often available only in standard dimensions and in sheet form, with foam board typically manufactured in 4 foot by 8 foot sheets.

- Affordability. XPS foam board is very affordable and is one of the most economical of the rigid foam board options on the market. For example, a one-inch thick XPS foam board costs about $0.47 per square foot on average.

- Energy efficiency. Extruded Polystyrene is an energy-efficient building material. Over the lifetime of a building insulated with XPS foam board, a lot more energy is saved compared to the energy used during the manufacturing process.

- Sustainability. Since polystyrene resin is used in manufacturing XPS foam board, the foam board can be melted down and reused to produce new XPS insulation.

- Many uses. Extruded polystyrene and eps foam board have many uses such as thermal insulation and are used in many insulation products and fiberglass products.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5798

Extruded Polystyrene Market Report Scope

| Report Attribute | Details |

| Market size value in 2025 | USD 7.61 Billion |

| Revenue forecast in 2034 | USD 12.70 billion |

| Growth rate | CAGR of 5.85% from 2025 to 2034 |

| Historical data | 2021 - 2025 |

| Forecast period | 2025 - 2035 |

| Quantitative units | Revenue in USD million, volume in kilotons, and CAGR from 2025 to 2034 |

| Report coverage | Revenue forecast, competitive landscape, growth factors, and trends |

| Report Segmentation | By Product Type, By Application, By End-Use Area (Insulation Focus), By Distribution Channel, By Region |

| Regional scope | North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

| Country Scope | U.S., Canada; Mexico; Germany; UK; France; Italy; Spain, China; India; Japan; South Korea, Australia Brazil; Argentina, Saudi Arabia, South Africa, UAE |

| Key companies profiled | BASF SE: (Germany), Owens Corning: (U.S.), Kingspan Group Plc: (Ireland),DuPont: (U.S.), Saint-Gobain: (France), Ravago S.A.: (Belgium), Dow Inc. (U.S.), Kaneka Corporation: (Japan), Knauf Insulation: (Germany), Synthos S.A.: (Poland), Supreme Petrochem Ltd. (India), Austrotherm GmbH: (Germany), Soprema Group: (France), Emirates Extruded Polystyrene L.L.C.: (UAE), TechnoNICOL Corporation (Russia), Jackon Insulation GmbH: (Germany) |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

Smart Insulation: How AI Is Revolutionizing the Extruded Polystyrene Industry

AI is transforming the extruded polystyrene (XPS) industry by optimizing production processes, enabling precise control over density, thickness, and thermal performance to meet stringent insulation standards. Machine learning algorithms help manufacturers predict equipment maintenance needs, reduce downtime, and minimize energy consumption, improving operational efficiency. AI-powered quality monitoring systems detect defects in real time, ensuring consistent product performance and reducing waste. Additionally, AI-driven supply chain analytics allow producers to forecast demand accurately, streamline distribution, and support sustainable, cost-effective production strategies across construction, packaging, and industrial applications.

Key Private Industry Investments in the Extruded Polystyrene Industry

- Owens Corning expanded its U.S. production of FOAMULAR NGX variants in October 2025, with an investment focused on creating products with 90% recycled content to align with new EPA ENERGY STAR guidelines and boost thermal performance.

- BASF SE divested its Styrodur extruded polystyrene insulation business to Karl Bachl Kunststoffverarbeitung GmbH & Co. KG in January 2025, enabling BASF to strategically focus on growing its expandable polystyrene (EPS) business.

- Karl Bachl Kunststoffverarbeitung GmbH & Co. KG completed the acquisition of BASF's Styrodur XPS business in January 2025, expanding its own insulation portfolio with a well-established and high-quality XPS brand.

- LP Building Solutions partnered with Owens Corning in April 2024 to create composite panels for its NovaCore product line, which uses FOAMULAR XPS boards to combine structural strength with high R-value insulation.

-

Ravago Group has been identified as a key player actively pursuing product launches and partnerships within the XPS market to attract a larger market share globally.

Key Trends of the Extruded Polystyrene Market:

- Rising Demand for Energy-Efficient Building Materials – Increasing focus on thermal insulation in residential and commercial construction is driving adoption of XPS due to its superior R-value and moisture resistance. Governments and building codes worldwide are encouraging energy-efficient construction, boosting demand for XPS in walls, roofs, and floors.

- Advancements in Flame-Retardant and Eco-Friendly Formulations – Manufacturers are developing XPS boards with enhanced fire resistance and lower environmental impact to meet stricter safety and sustainability regulations. These innovations improve market acceptance and expand applications in sensitive areas such as high-rise buildings and cold-chain packaging.

-

Integration of AI and Automation in Manufacturing – AI-driven process optimization and predictive maintenance are enhancing production efficiency, reducing material waste, and ensuring consistent product quality. Automation and real-time monitoring also help XPS producers meet growing demand while controlling operational costs and energy consumption.

Market Opportunity

Construction Insulation Leads the Way: Driving the Extruded Polystyrene Market

The construction and building insulation sector represent the major market for extruded polystyrene (XPS), fueled by the growing need for energy-efficient, durable, and moisture-resistant materials in residential, commercial, and industrial projects. XPS is widely used in walls, roofs, floors, and foundations due to its high thermal resistance, compressive strength, and long-term performance, helping buildings meet stringent energy codes. Rapid urbanization, rising infrastructure development, and government incentives for green and energy-efficient construction are further accelerating demand.

What are the advantages of extruded polystyrene insulation?

XPS offers a variety of advantages compared to other insulation materials such as EPS. First, the closed cells of TECHNONICOL CARBON XPS are small and uniform, creating greater and more consistent thermal resistance throughout the material while reducing the likelihood of water absorption. XPS by TECHNONICOL is lightweight but provides incredible compression and bending strength, making it ideal for terraces, operated roofs, foundations and roadways. XPS is environmentally safe, given the lack of off-gassing and associated contaminants produced during manufacturing, and less insulation is needed to create greater thermal insulation, allowing contractors to use less material and reduce costs. Given that this product does not rot or decompose and can withstand temperatures from -70 to 75 degrees Celsius, users are guaranteed an exceptionally long service life.

Types of XPS

- TECHNONICOL CARBON ECO is used for insulation of roofs, basements and floors. It comes in thicknesses ranging from 10 to 100 mm and can withstand over 200 kPa of compressive force with 10% of deformation. The material is commonly used in low-rise construction.

- TECHNONICOL CARBON ECO FACADE is specifically milled to be used for plaster facades and plinths, with grooves that ensure adherence of plaster for maximum durability. It has similar dimensional and compressive properties as TECHNONICOL CARBON ECO. Given its high strength properties, it helps to maintain the integrity and impact resistance of plaster facades.

- TECHNONICOL CARBON PROF 300 offers even greater compressive strength, providing resistance of at least 300 kPa. This material is used in basements, floors and roofs similar to the CARBON ECO and comes in thicker dimensions of up to 200 mm, allowing it to be used in more complicated applications such as highways, railways and other large commercial projects.

- TECHNONICOL CARBON SOLID 500 offers the greatest compressive strength of a minimum of 500 kPa, allowing it to be used in large-scale commercial buildings with increased requirements and special infrastructure projects such as runways, bridges and tunnels.

All slabs of TECHNONICOL CARBON extruded polystyrene can come with flat or L-shaped edges as per the project requirements.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5798

Extruded Polystyrene Market Segmentation Insights

Product Type Insights

The boards segment led the market in 2024 because it offers high structural strength, excellent thermal insulation, and moisture resistance, making it ideal for construction applications such as walls, roofs, and floors. Boards are easy to handle, cut, and install, which reduces labor costs and construction time while maintaining consistent performance. The ability to produce boards in a variety of thicknesses and densities allows manufacturers to meet diverse building requirements and energy-efficiency standards.

The sheets segment is growing fastest in the market because it provides versatile, uniform, and easily fabricated material for applications in construction, industrial insulation, and packaging. Sheets offer consistent thickness, high compressive strength, and excellent thermal and moisture resistance, making them suitable for walls, roofing, flooring, and cold-storage applications. Their ease of cutting, shaping, and layering allows for customization in both small- and large-scale projects, enhancing their utility across multiple industries.

Application Insights

The residential construction segment led the market in 2024 because homeowners and builders increasingly prioritized energy-efficient and durable insulation for walls, roofs, and floors. XPS offers excellent thermal resistance, moisture protection, and long-term performance, making it ideal for maintaining indoor comfort and reducing energy costs. Its lightweight nature, ease of installation, and compatibility with various building materials further supported widespread adoption in residential projects.

The infrastructure segment is growing fastest over the forecast period due to the growing demand for durable, high-performance insulation in roads, bridges, tunnels, and public utility projects. XPS provides excellent compressive strength, moisture resistance, and thermal insulation, which are critical for long-term stability and protection in large-scale infrastructure applications. Its lightweight and easy-to-install nature reduces construction time and costs while maintaining structural integrity.

End-use Area Insights

In 2024, the wall insulation segment led the market because XPS offers superior thermal resistance, moisture protection, and durability, making it ideal for enhancing energy efficiency in residential, commercial, and industrial buildings. Its lightweight and easy-to-install panels simplify construction and renovation processes, reducing labor and material costs. XPS boards and sheets can be produced in various thicknesses and densities, allowing customization to meet different wall designs and building codes.

The foundation & basement insulation segment is growing fastest over the forecast period because XPS provides excellent moisture resistance, compressive strength, and long-term durability, which are critical for protecting structures below ground. Its thermal insulation properties help prevent heat loss and improve energy efficiency in basements and foundations. The material’s lightweight, easy-to-install boards simplify construction and retrofit projects while maintaining structural integrity.

Distribution Channel Insights

The construction material distributors segment led the market in 2024 because distributors provide wide-reaching access to XPS products for builders, contractors, and retailers, ensuring timely supply and consistent availability. Their established logistics networks and bulk supply capabilities reduce procurement complexity and costs for end-users. Distributors also offer technical support, product variety, and customized solutions, helping customers select the right XPS boards or sheets for specific applications.

The online platforms segment is expected to lead the market over the forecast period because digital marketplaces provided manufacturers, distributors, and contractors with efficient, transparent, and fast access to XPS products. These platforms allowed users to compare specifications, pricing, and availability in real time, simplifying procurement and reducing lead times. The convenience of online ordering and home or project-site delivery enhanced adoption among small and medium-sized builders as well as large contractors.

Regional Insights

Europe Sets the Standard: Leading the Global Extruded Polystyrene Market

Europe dominates the market due to its strong construction and infrastructure sectors, stringent energy-efficiency regulations, and widespread adoption of sustainable building materials. Government incentives and building codes promoting high-performance insulation have accelerated the use of XPS in residential, commercial, and industrial projects. Additionally, the region’s well-established manufacturing base and focus on R&D in fire-retardant and eco-friendly XPS formulations have reinforced Europe’s leadership.

Germany Extruded Polystyrene Market

Germany’s market is growing steadily, driven by strong demand for energy-efficient and durable insulation materials in residential, commercial, and industrial construction. Strict building codes, sustainability regulations, and government incentives are encouraging the adoption of XPS for walls, roofs, floors, and foundation insulation. Advances in fire-retardant and eco-friendly formulations have further expanded applications and improved performance. Additionally, ongoing renovation projects, infrastructure development, and the focus on green building standards continue to support market growth in Germany.

Asia-Pacific on the Rise: The Fastest-Growing Extruded Polystyrene Market

Asia-Pacific is witnessing the fastest growth in the market due to rapid urbanization, large-scale infrastructure development, and expanding residential and commercial construction projects. Rising demand for energy-efficient buildings and government initiatives promoting green construction are accelerating XPS adoption across countries like China, India, Japan, and Southeast Asia. The region’s growing manufacturing capabilities and cost advantages further support the production and supply of high-performance XPS products.

India Extruded Polystyrene Market

India’s market is experiencing rapid growth, fueled by increasing urbanization, infrastructure development, and a rising focus on energy-efficient construction. The material’s superior thermal insulation, moisture resistance, and durability make it ideal for residential, commercial, and industrial building applications. Government initiatives promoting green buildings and sustainable construction practices are further accelerating adoption. Additionally, growing awareness among builders and developers about long-term energy savings and cost efficiency is driving demand for XPS across the country.

North America Extruded Polystyrene Market

North America held the largest share of 43.36% in revenue of the extruded polystyrene market in 2024. Municipal and state governments across Canada and the United States are implementing stricter building codes that require higher thermal insulation values in both new and existing structures. This regulatory effort is encouraging property owners to upgrade aging envelopes with extruded polystyrene (XPS) panels to achieve measurable energy savings. Incentive programs for retrofit projects are speeding up replacement cycles, especially in regions with harsh winters where energy bills are a major operating cost. Consequently, manufacturers are focusing on partnerships with retrofit specialists to seize this growing market segment.

The surge in e-commerce and perishable goods distribution is driving unprecedented growth in cold storage warehouses and refrigerated transport hubs. Operators are choosing extruded polystyrene for its superior moisture resistance and reliable insulation performance under heavy traffic. Major logistics developers are integrating XPS into slab-on-grade and mezzanine designs to ensure product integrity and reduce energy consumption. This rapid growth of temperature-controlled facilities is creating a steady demand for high-performance XPS boards.

U.S. Extruded Polystyrene Market Trends

The Inflation Reduction Act continues to provide substantial tax credits and grants for energy-efficient building materials, making XPS an appealing choice for commercial and residential developers. Along with Department of Energy funding for pilot projects in affordable housing, these incentives effectively reduce the upfront cost of advanced insulation solutions. As architects and specifiers respond to these financial incentives, extruded polystyrene is becoming more prominent in government-supported construction projects aimed at achieving net-zero operational emissions.

Top Companies in the Extruded Polystyrene Market & Their Offerings:

Tier 1:

- BASF SE: Offered the Styrodur XPS brand before divesting the business to focus on other insulation materials.

- Owens Corning: Manufactures the FOAMULAR line of pink XPS insulation boards known for moisture resistance and lower global warming potential.

- Kingspan Group Plc: Provides Kingspan GreenGuard XPS insulation, specifically tailored for high-performance applications like inverted roofs and heavy-duty flooring.

- DuPont: Produces the Styrofoam brand XPS insulation, offering grey-colored, closed-cell foam boards with low global warming potential formulations.

- Saint-Gobain: Offers various insulation solutions, including XPS products, as part of its broad portfolio of building materials for sustainable construction.

- Ravago S.A.: Manufactures and distributes blue RAVATHERM XPS X products, which are robust, closed-cell insulation boards for multiple building and industrial uses.

- Dow Inc.: Historically created the Styrofoam brand but sold the XPS business to DuPont, now providing other material science solutions for construction.

- Kaneka Corporation: Produces Kanelite Foam α, a high-performance XPS product designed for superior thermal insulation in Japanese residential and commercial buildings.

-

Knauf Insulation: Focuses primarily on mineral wool and EPS insulation, and does not list an extruded polystyrene offering within its core product lines.

More Insights in Towards Chemical and Materials:

- U.S. Extruded Polystyrene Market Size to Hit USD 3.24 Billion by 2034

- Recycled Polystyrene Market Size to Hit USD 7.49 Bn by 2034

- Expandable Polystyrene Market Volume to Reach 9.33 Mn Tons By 2034

- Polystyrene Market Volume to Reach 62.33 Million Tons by 2034

- Polyethylene Terephthalate Catalyst Market Size to Hit USD 1,321.75 Mn by 2034

- Polyethylene Glycol (PEG) Market Volume to Exceed 788,565.1 Tons by 2034

- Polyethylene Terephthalate (PET) Market Size to Reach USD 68 Bn by 2034

- Polyethylene Wax Market Size to Reach USD 3.56 Bn By 2034

- Mechanical & Chemical Recycling of Polyethylene Market Size, Share | CAGR of 10.29%

- Low-Density Polyethylene (LDPE) Market Size to Reach USD 80.34 Billion by 2034

- Polyethylene Market Volume to Hit 158.1 Million Tons by 2034

- Plastic Compounding Market Size to Reach USD 148.83 Bn by 2034

- Polymers Market Size to Reach USD 1,351.59 Billion by 2034

- Recycled Plastics Market Size to Surpass USD 190.25 Billion by 2035

-

Polyethylene Terephthalate (PET) Market Size to Reach USD 68 Bn by 2034

Extruded Polystyrene Market Top Key Companies:

- BASF SE: (Germany)

- Owens Corning: (U.S.)

- Kingspan Group Plc: (Ireland)

- DuPont: (U.S.)

- Saint-Gobain: (France)

- Ravago S.A.: (Belgium)

- Dow Inc. (U.S.)

- Kaneka Corporation: (Japan)

- Knauf Insulation: (Germany)

- Synthos S.A.: (Poland)

- Supreme Petrochem Ltd. (India)

- Austrotherm GmbH: (Germany)

- Soprema Group: (France)

- Emirates Extruded Polystyrene L.L.C.: (UAE)

- TechnoNICOL Corporation (Russia)

- Jackon Insulation GmbH: (Germany)

Recent Developments

- In June 2025, BASF SE completed the sale of its Styrodur extruded polystyrene (XPS) insulation business, including the brand, to German manufacturer Karl Bachl Kunststoffverarbeitung GmbH & Co. KG (BACHL), after regulatory approvals.

- In April 2024, SOPREMA announced the renaming of its extruded polystyrene (XPS) insulation products. The change aimed to provide clearer and more consistent product names reflecting key attributes like compressive strength, surface type, edge type, and dimensional stability, while maintaining the same product quality.

- In March 2024, Owens Corning introduced manufacturing achievements to help reduce the environmental footprint of buildings. The company has announced the full conversion of its extruded polystyrene (XPS) insulation production of FOAMULAR NGX in all U.S. and Canadian plants.

Extruded Polystyrene Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2034. For this study, Towards Chemical and Materials has segmented the global Extruded Polystyrene Market

By Product Type

- Boards

- Sheets

- Blocks

- Others (Foam Panels, Customized Shapes)

By Application

- Residential Construction

- Commercial Construction

- Industrial Buildings

- Infrastructure (Roads, Bridges, Airports, Railways)

By End-Use Area (Insulation Focus)

- Wall Insulation

- Roof Insulation

- Floor & Ceiling Insulation

- Foundation & Basement Insulation

- Others (Cold Storage, Industrial Uses)

By Distribution Channel

- Direct Sales to Contractors & Builders

- Construction Material Distributors

- Retail/Hardware Stores

- Online Platforms

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5798

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | Towards Consumer Goods | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.